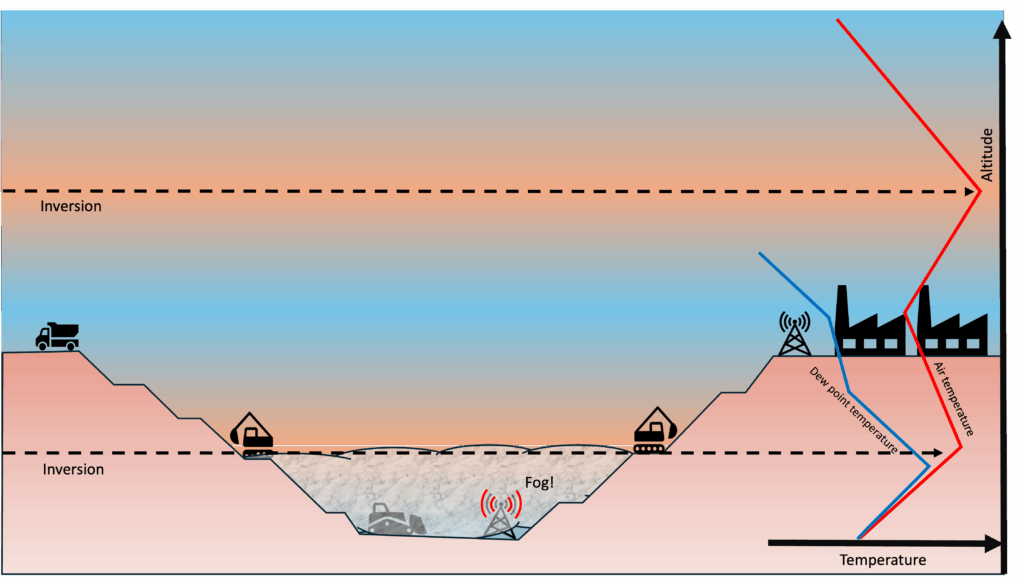

Weather such as low cloud, fog, gusty winds, dispersion of dust, smoke and other pollutants, and blast sound shockwaves can all be the result of inversions and have significant impacts on safe and responsible mining operations.

What is a temperature inversion?

In the troposphere, the atmosphere layer closest to the ground and where most of the weather is played out, the air temperature typically decreases with height.

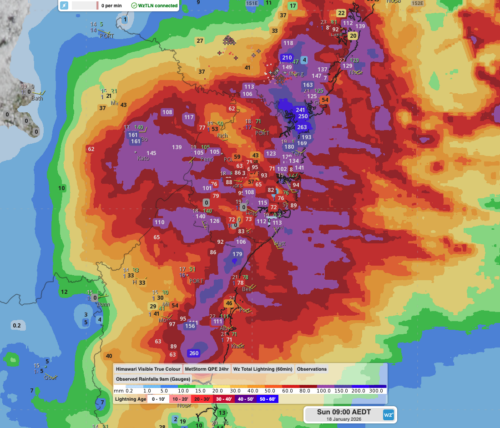

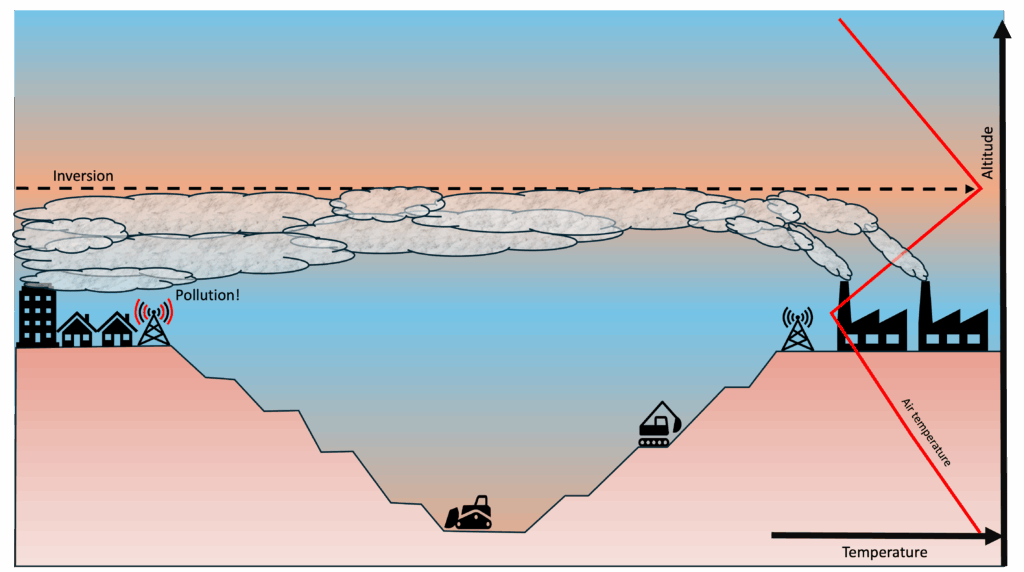

A temperature inversion is when, you guessed it, the inverse happens. In an atmospheric inversion layer, the air temperature increases with height. The red line in the figure below depicts the air temperature increasing with height up to the inversion ceiling.

Image: air temperature increases with height in the inversion layer, trapping pollution below the inversion.

Cooler air is denser than warm air, so the cooler air naturally wants to be below the warm air, meaning inversion layers are very stable. This will be very important shortly.

Why do inversions matter to mining?

Because of their stability, inversions act like a bubble or shield above the surface. This can trap dust, smoke, pollutants and even sound under the inversion – all considerations that mining operations need to be wary of to meet regulations. Inversions can also signify the formation of fog, reducing visibility, and can alter local wind patterns.

Fog

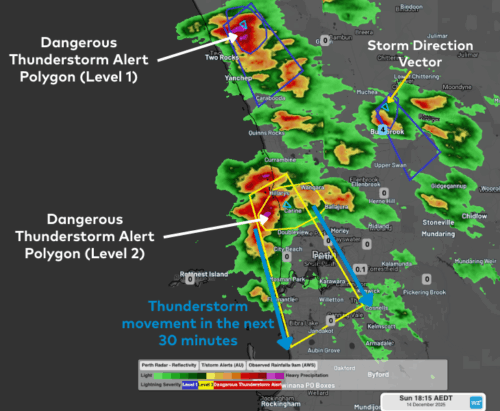

Inversions and fogs go hand in hand. At night, the surface air temperature cools much faster than the atmosphere above. This is how most inversions that impact mines occur.

Image: diagram showing fog forming within an open cut mine, which takes much longer to warm at the bottom, leading to long lasting fogs.

As the inversion strengthens, the surface temperature may cool enough to reach its saturation point if there is enough moisture in the atmosphere. At this temperature, the air is saturated with moisture, and cloud droplets form – the visibility drops, and we have our fog.

Video: widespread fog across Victoria and southern NSW lingering throughout the morning and into the afternoon of Friday, June 13, under a strong subsidence inversion.

In heavy fogs, which are common around mining areas, visibility is reduced to only a few metres, posing a major safety hazard. Personnel driving or operating heavy machinery are forced to slow down or stop completely, effectively halting operations across the entire mine for several hours, until the fog clears.

Image: Visibility in heavy fog can be reduced to only a few metres. Source: iStock / middelveld

Miningzone, DTN APAC’s customisable mining dashboard, offers fog risk, density, and onset and clearance times forecasts out to seven days. Our accurate and easy to use forecasts allow mines to maintain safety and efficiency, effectively saving mine sites millions of dollars, rather than being caught out and sitting around waiting for the fog to clear.

Image: Miningzone Operational Forecast Summary showing simple and easy-to-read fog risk, with hourly breakdown for maximum planning capacity.

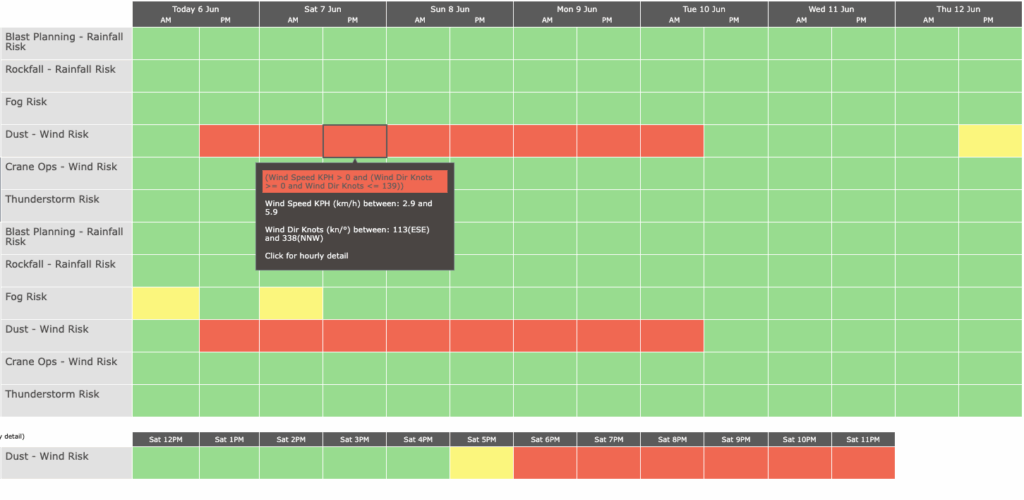

Miningzone uses a simple traffic light system, with green having no impact on operations, yellow a moderate impact, and red a high impact. Our Opticast model is fine tuned to your individual mine site requirements and local topography, producing forecast alerts for fog risk and density down to the hour, enabling optimal decision making well in advance.

Video: fog lingering along valleys and mine areas to the southeast of Perth on Sunday, June 8.

Fog can also linger much longer within large open cut mines, which act as man-made valleys and see delayed sunlight – which “burns off” the fog. DTN APAC offers simple to install weather stations with ongoing maintenance support provided. The compact, all-in-one weather sensor can be placed within the mine, giving crucial operational intel on the formation and clearance of fog, as well as a number of other important weather elements.

Dust and blast dispersion

Image: uncontrolled blast mining dust dispersion can lead to costly regulation fines. Source: iStock / Ghulam Hussain

The stable nature of inversions also affects particulates and sound – acting as a barrier to the remainder of the atmosphere. Dust, smoke, pollution and sound can become trapped close to the ground under inversions. Unable to disperse throughout the atmosphere, the concentrations remain elevated, which can become a huge cost if above regulations, or if impacting populated areas. Sound from the blast can also bounce off inversions, arriving as a concentrated shock wave that can shatter windows and burst eardrums in populated areas.

Image: diagram showing smoke and pollution remaining trapped under an inversion.

DTN APACs easy-to-use Blast Modelling system delivers accurate and concise information on every planned blast. EPA approved dispersion modelling is combined with high precision, site-specific forecasts, and integrated environmental observations to deliver a complete environmental picture of client sites.

Video: DTN APACs Blast Modelling system dashboard showing simulated dust propagation.

Our system allows your business to plan the perfect blast window with respect to the expected weather conditions to remain compliant. The Blast system provides an auditable report trail of all executed blasts, stored in the cloud for any future legislative requirement investigations.

Image: Miningzone Operational Forecast Summary showing simple and easy-to-read Dust risk based on forecast wind speeds, with hourly breakdown for maximum planning capacity.

The DTN APAC systems can be scaled to your specific business requirements, allowing;

- Enhanced Safety: Predict fog conditions to protect personnel and equipment.

- Regulatory Compliance: Meet environmental standards with approved modelling.

- Operational Efficiency: Optimise blast timing to prevent costly delays.

- Risk Management: Control dust, smoke and sound dispersion effectively.

- Customised Forecasting: Solutions tailored to your mine’s specific needs.

Learn more about our large range of industry leading products and services or email us at sales.apac@dtn.com